Conventional NDT used for internal Inspection!

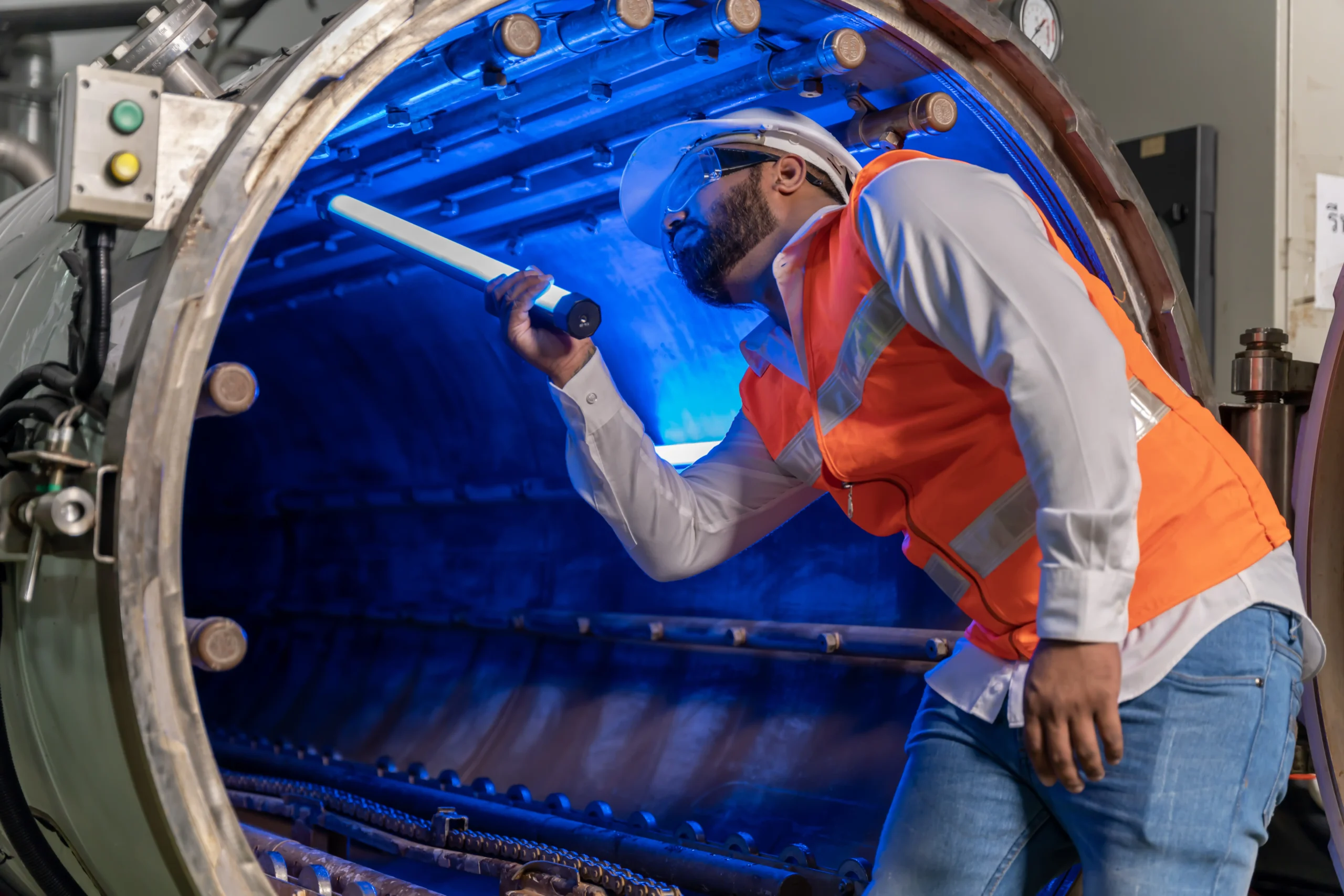

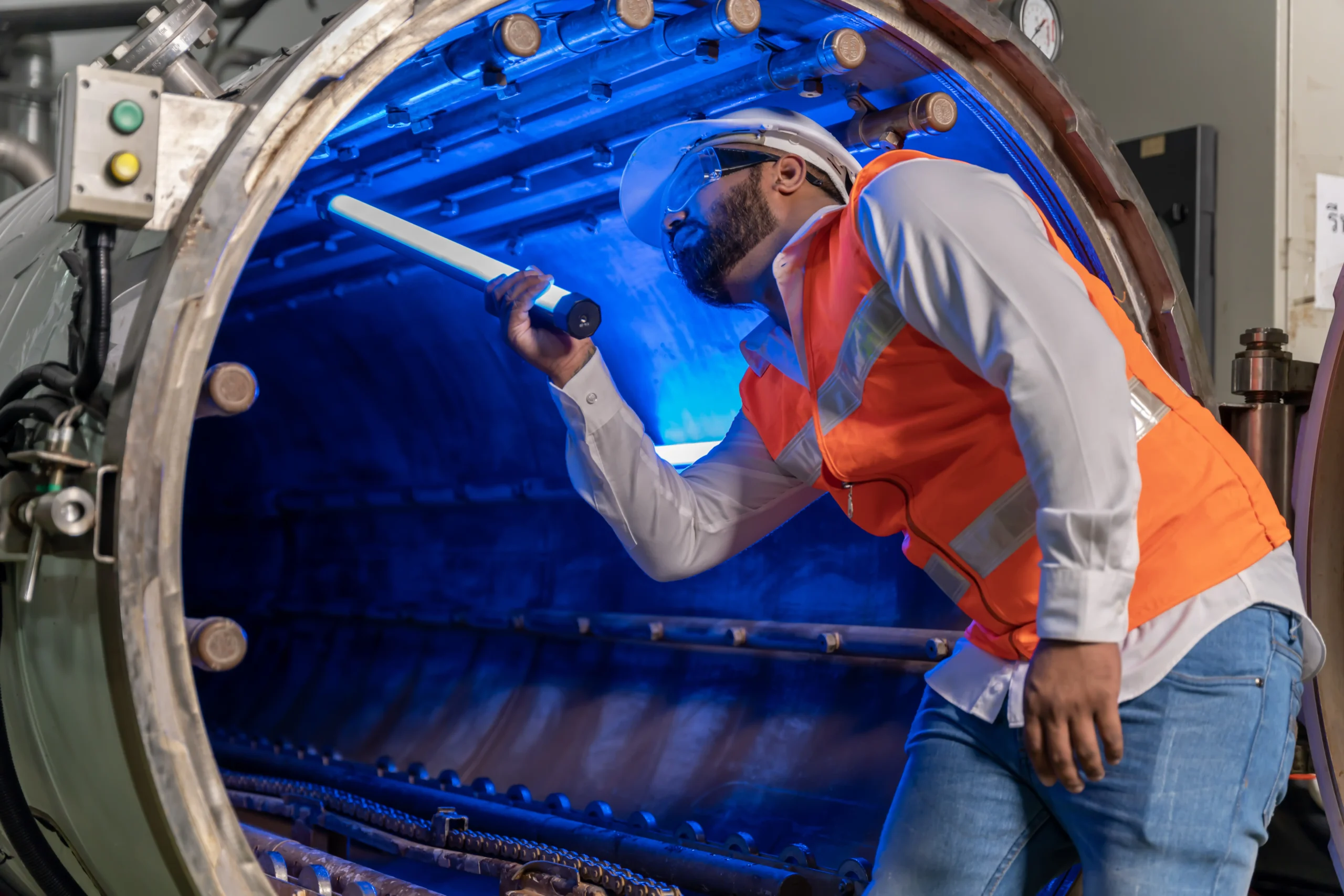

Visual Inspection.

VT is the fastest and cheapest method of Non-destructive

testing. It’s the first step of every inspection before any

other Non-destructive test starts. When performing visual

test with naked eye, equipment such as magnifying glass,

light source, borescope, and mirror can also be used.

Ultrasonic Testing

Wall Thickness & Metal Loses measurements using UT Thickness Gauges includes A-scan feature to able to detect corrosion failure and display reading in Digital & A-scan view.

Magnetic Testing

MT is essentially a surface –

type examination, although

some imperfections just below

the surface are detectable.

This type of examination is

limited to materials which can

be magnetized (hence it is not

appropriate for austenitic

stainless steels). An area to

be examined by magnetic

particle examination can be

completely examined or

examined on a random

sampling basis, as specified.

Penetrant Testing

MT is essentially a surface –

type examination, although

some imperfections just below

the surface are detectable.

This type of examination is

limited to materials which can

be magnetized (hence it is not

appropriate for austenitic

stainless steels). An area to

be examined by magnetic

particle examination can be

completely examined or

examined on a random

sampling basis, as specified.

Radiography Testing

Random R T X-ray or gamma ray

radiography may be used. The

selection of the method should be

dependent upon its adaptability to

work being radiographed. When

random radiography of welds is

specified by the engineering

design, it should be done on the

number of welds designated. The

engineering design shall specify

the extent to which each examined

weld should be radiographed.

Random radiography may also be

used for examination of piping

components such as a valve or

fitting to any extent specified by

the engineering design .